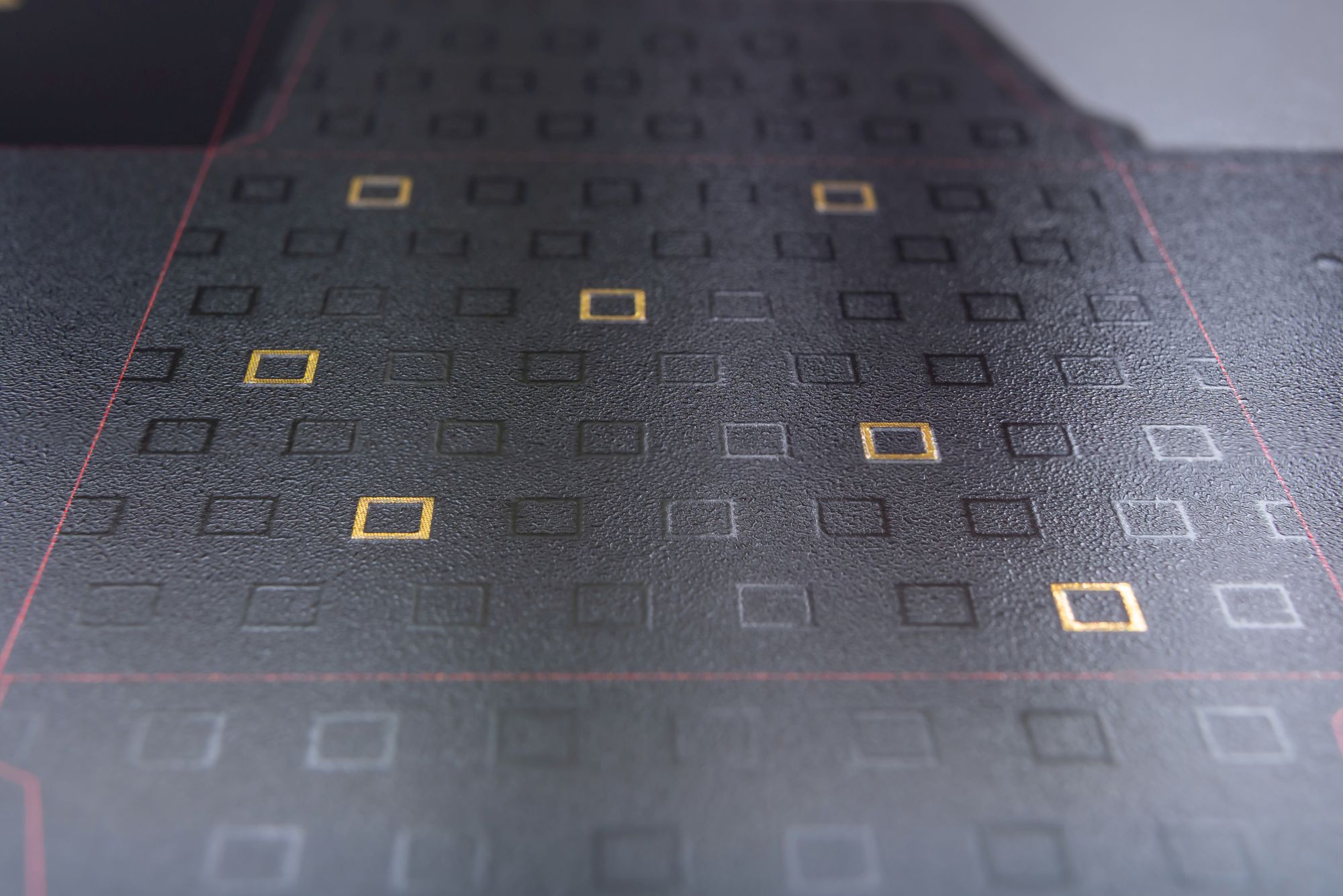

eye-catching varnishes

The eye-catching varnishes are a relatively new technology, but they are often used in the work of customers. Hybrid varnishes, as they are called, are achieved by using two types of paint simultaneously. The first one is applied selectively from an offset plate in places that are to have a structure effect, while the second one is applied to the entire print surface. This effect can be achieved in offset printing using oil varnish and UV gloss varnish. The porous structure effect is created as a result of the influence of not dried out oil lacquer on the gloss lacquer or UV lacquer applied on the whole surface. However, please note that, as with any varnish, hybrid varnish should be careful with some projects. Special attention should be paid to folding work, as the varnish may crack where the paper breaks. This phenomenon depends on the type of surface, weight and direction of fibers in the sheet. However, with proper packaging design you should not worry too much about it, as the risk is reduced to practically zero and the achieved effect rewards the effort related to the proper design of the cardboard.

In the case of packaging intended for food contact, we can use barrier or even antibacterial varnish.

An alternative to varnishes is lamination of printed sheets. In this case, we can apply a glossy, matt or soft touch foil to the boxes. The foils also differ in their resistance to mechanical damage. It is possible to laminate boxes with scratch protection foils or even antibacterial foils.

WARNING! We use cookies on our website on the terms set out in the Privacy Policy. By using the website without changing the settings, you accept these rules.

Find out more I understandIn order to display the website properly and to browse the Internet safely, we recommend using the latest version of the browser: Google Chrome, Mozilla Firefox, Opera or MS Edge.