preparing the files

In order to create a unique product, support in the field of graphic design is essential, and we also provide it. Experienced graphic designers in our studio will easily advise, adapt the design to individual needs and technical capabilities, based on materials sent by the client. In order to meet your expectations in terms of the quality of the final product, the materials for printing should be prepared according to the applicable printing rules. Below we have described the most important of them, which you should remember when preparing your project for printing:

- 1. THE WAY OF SUPPLYING THE MATERIALS FOR PRINTING

- 1.1 Digital formatted materials on PC systems shall be delivered by e-mail, FTP, WeTransfer, Dropbox or other online file transfer service. We also accept physical digital media: CD, DVD, Flash Drive;

- 1.2 We accept OPEN files in *AI, *EPS, *CDR to X4, *PDF to 1.5, compatible with the PDF/X-4 printing standard;

- 1.3 Please add a low resolution view in *.jpg format to the actual files. or pdf format;

- 1.4 The time of delivery of digital materials shall be regarded as the time of delivery of complete, unaltered materials;

- 1.5 We do not accept Microsoft Word (DOC, DOCX) and PowerPoint (PPT, PPS) files.

- 2. THE WAY OF PREPARING MATERIALS FOR PRINTING

- 2.1 BLEEDS:

- Printing bleed for solid cardboard packaging: 2,5-3mm; for laminated packaging: 4-5mm

- All-important graphic elements of the design should be at a minimum distance from the edge of the target format (cutting line) 4-5mm for laminated packaging and 2-2,5mm for solid cardboard packaging.

- 2.2 COLOURS:

- Printing technique: Offset

- Maximum number of colours: CMYK + 3 SPOT

- Materials must be prepared in the colour space (mode) CMYK

- We recommend the European standard Fogra 39

- Black texts should be obtained by using only black colour

- As 'deep black', we propose using values: C30 M30 Y20 K100

- Maximum colouring: 300-320%

- Black objects (K100) should be printed (overprinted) if technically possible

- 2.3 PHOTOS:

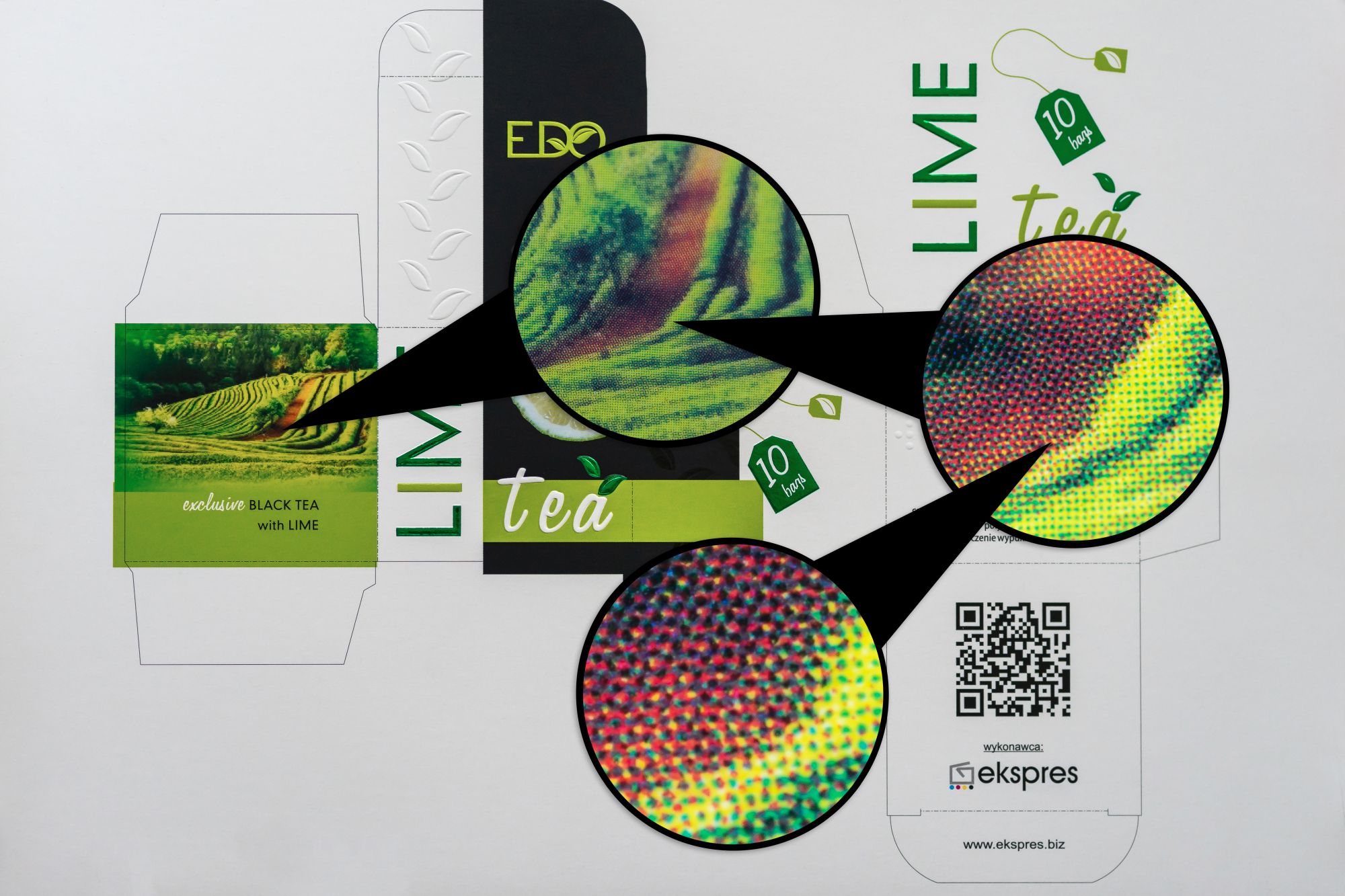

- Bitmaps (photos) should be at least 300 ppi. Below this value the quality of the image is lost - a clear pixilation. In case of replacing texts or other small vector elements with a bitmap, we recommend a resolution of at least 600ppi. Black and white graphics should be saved in grayscale mode (i.e. containing only black colour). The transmission of a graphic with a lower resolution means that you accept that the quality of the image will be reduced.

- 2.4 LETTER AND LINES:

- All texts should be converted into vectors.

- The minimum degree of print in one colour is one colour:

- for one-piece fonts 5 pt

- for two-piece cuts 6 pt

- The minimum degree of printing in more than 1 colour or in reverse is:

- for one-piece cuts 6 pt

- for two-piece cuts 8 pt

- The minimum permitted line thickness is 0,3 pt. Lines made in counter - or more than one colour should be not less than 0,5 pt.

- 2.5 TRAPPING:

- In order to avoid mismatches, trapping, i.e. minimal overlapping of colours, is necessary. The recommended trapping value is 0,1 mm. For text in contrast to black background, it is advisable to use 0,05 mm negative traps for CMY colours (in other words, outline around the text only with K-component: 100% without adding other colours).

- 2.6 REFINEMENTS:

- If the work involves selective varnish, embossing or hot stamping should be prepared as a spot colour. Selective lacquer, embossing, hot stamping - prepared in vectors, min. element thickness 0.35mm.

- 2.7 DIE-CUTS:

- Place 0.5 mm thick die-cut lines directly on the project and give them additional colour and overprint.

Each time the printing house verifies the correctness of the materials provided by the customer, however, it does not guarantee that all errors and inconsistencies in respect to the above specification will be noticed. Additional operations aimed at adjusting files to the compliance with the specification and all changes made by the Printing House at the Customer's request are treated as an additional PAYABLE service.

Download the technical specifications for preparing files for printing: